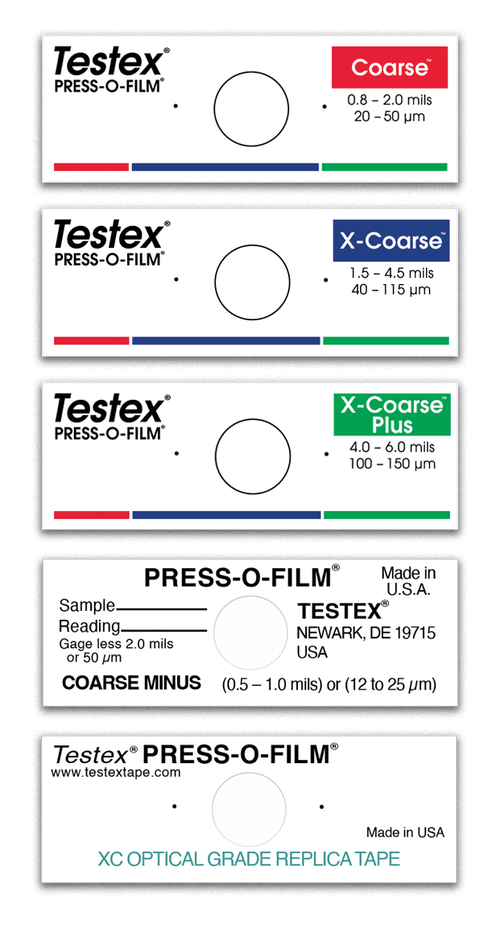

| Grade | Profile Range | Typical Use / Notes |

|---|---|---|

| Coarse Minus | 0.5 – 1.0 mils (12 – 25 µm) | For very smooth blast profiles and fine surface preparation. |

| Coarse | 0.8 – 2.0 mils (20 – 50 µm) | General-purpose grade for most steel blast-cleaned surfaces. |

| X-Coarse | 1.5 – 4.5 mils (40 – 115 µm) | Common choice for typical industrial blasting and coating work. |

| X-Coarse Plus | 4.0 – 6.0 mils (100 – 150 µm) | For extra-rough profiles where heavy-duty coatings will be applied. |

Testex® Replica Tape

£35 + VAT

Instant, Proven Surface Profile Measurement

Testex® Press-O-Film™ Replica Tape is the industry-standard way to capture and measure the peak-to-valley profile of blasted steel and other prepared surfaces.

By simply burnishing the tape onto the surface and measuring the impression with a calibrated micrometer or PosiTector RTR, you obtain a permanent physical record of the surface profile—ideal for quality control, contract compliance, and traceable inspection records.

In addition to its ease of use, replica tape provides a unique combination of versatility and traceability. Unlike electronic gauges that require direct probe contact, Testex tape conforms to complex shapes, curved pipework, or irregular textures while preserving an enduring impression of the surface.

This makes it especially valuable on projects where documentation and long-term verification are essential, such as critical infrastructure, marine coatings, and industrial maintenance programmes.

Features

-

Creates a True Surface Replica – Press the foam against the prepared substrate to form a permanent impression of the surface profile for precise measurement.

-

Trusted Foam in Convenient Strips – Available in the familiar Coarse and X-Coarse grades, now supplied in an easy-to-handle strip format.

-

Straightforward Process – Simply place, burnish, remove, and measure—a quick, clean technique that requires no specialised training.

-

Independent Validation – Proven accuracy and repeatability, confirmed by multiple independent studies over decades of industry use.

-

Flexible Measurement Options – Read the impression using a precision digital or analogue micrometer, or a PosiTector RTR digital replica-tape reader.

-

Fast Results – Each measurement typically takes under 30 seconds, even in field conditions.

-

Globally Recognised Method – The only surface-profile measurement technique endorsed by ISO, ASTM and AMPP, accepted worldwide for coating-prep verification.

-

Standards Compliant – Fully conforms to ASME B46, ASTM D4417, ISO 8503-5, NACE SP0287, SSPC-PA 17, SP5, SP6, SP10, SP11-87T, and related international standards.

Why Measuring Matters

-

Assured Coating Adhesion – Correct peak-to-valley surface profile is critical for long-lasting paint or protective coatings. Too shallow and the coating may not bond; too deep and peaks can remain uncoated, encouraging early corrosion.

-

Permanent Physical Record – Each impression provides a physical sample of the blasted surface that can be archived for QA documentation, client sign-off, or dispute resolution years later.

-

Works Where Probes Can’t – Because the compressible foam conforms to curved, rough, or hard-to-reach areas, it is ideal for pipes, tanks, and other complex structures where direct probe measurement is impractical.

-

Globally Accepted Method – Replica tape is the only surface-profile measurement technique recognised by ISO, ASTM, and AMPP, and is specified in many project tenders and international standards.

-

Quick and Repeatable – Simple burnish-and-measure process gives reliable results in under 30 seconds, with proven accuracy validated by numerous independent studies.

Why Choose DFT?

-

DeFelsko Expertise Since 1998 – DFT has been the UK distributor for DeFelsko precision instruments for over 25 years, providing unrivalled product knowledge and direct manufacturer support.

-

Authorised UK Service & Calibration – As a DeFelsko Authorised Service Centre, we offer local calibration, repair, and technical support, ensuring fast turnaround without the need to ship overseas.

-

Comprehensive Stock & Accessories – We carry the full range of replica tape grades, burnishing tools, and micrometers, so you can source everything from a single trusted supplier.

-

Technical Guidance – Our team provides hands-on advice for grade selection, burnishing technique, and best practice to help you achieve consistent, standard-compliant results.

-

Reliable Delivery & Support – UK-based inventory and responsive customer service mean you can order with confidence and keep your projects on schedule.

Features & Benefits

-

Creates an exact replica of the blasted surface for accurate measurement.

-

Same trusted Coarse and X-Coarse foam now offered in convenient strip format.

-

Simple technique: place, burnish, remove and measure—no specialised training needed.

-

Proven accuracy and repeatability confirmed by multiple independent studies.

-

Compatible with a precision digital or analogue micrometer or a PosiTector RTR / RTR 3D digital replica-tape reader.

-

Typical measurement cycle takes less than 30 seconds.

-

Only surface-profile method recognised by ISO, ASTM and AMPP.

-

Conforms to ASME B46, ASTM D4417, ISO 8503-5, NACE SP0287, SSPC-PA 17, SP5, SP6, SP10, SP11-87T, and related international standards

Standard Testex® Replica Tape Grades

Optical-Grade Replica Tape (for 3D Measurements)

| Grade | Profile Range | Recommended Measurement Tool |

|---|---|---|

| Optical Grade X-Coarse | 1.5 – 4.5 mils (40 – 115 µm) | Designed for use with PosiTector RTR 3D to generate high-resolution 2D/3D surface data files (.SDF). |

How It Works:

Prepare the Surface

Ensure the blasted surface is clean and dry.

Burnish the Tape

Place a piece of Testex tape on the surface and firmly rub with the supplied burnishing tool until the foam is fully compressed into the surface profile.

Remove and Measure

Peel off the tape and measure the impression with a calibrated digital or analogue micrometer, or insert it into a PosiTector RTR or RTR 3D for digital analysis.

Testex Replica Tape FAQ’s

How many measurements are in a roll?

Each roll of Testex replica tape contains 50 single-use impressions. Every piece is individually protected, so you get consistent performance from start to finish. In practice, inspectors often take several impressions in a given area to capture variability, meaning a single roll can cover multiple panels, lengths of pipe, or defined inspection zones.

Does the tape itself need calibration?

No. The tape itself does not require calibration. Testex replica tape is manufactured with a tightly controlled backing thickness and compressible foam layer, so the only item that needs verification is the micrometer or digital reader you use to measure it. As long as that instrument is calibrated and used correctly, your readings will be accurate and standards-compliant.

How long can impressions be stored?

Impressions can be stored indefinitely provided they are kept clean, dry, and protected from physical damage. Once measured and documented, each piece of replica tape becomes a permanent physical record of the blasted surface. Many users file impressions alongside QA documentation, client sign-off sheets, and warranty records to provide traceable evidence years after the work is completed.

Which grade should I use?

Grade choice depends on the expected surface profile. Coarse Minus suits very smooth blast profiles, while Coarse covers most general-purpose steel preparation. X-Coarse is the most common choice for typical industrial blasting, and X-Coarse Plus is reserved for very rough profiles where heavy-duty coatings will be applied. If you’re unsure, matching the specified profile range in your job standard to the grade ranges listed on this page is a good starting point.

Can the Testex tape be used on curved or irregular surfaces?

Yes. One of the biggest advantages of replica tape is that it conforms to curved, rough, or complex shapes. The flexible backing and compressible foam allow you to take reliable impressions on pipes, tanks, flanges, welds, and difficult geometries where direct contact probes may struggle. This makes it ideal for in-situ work on plant and infrastructure, not just flat panels.

Is replica tape recognised by international standards?

Yes. Testex replica tape is specifically cited in major international standards, including ISO 8503-5, ASTM D4417 Method C, NACE SP0287, and SSPC-PA 17, among others. It is widely accepted by asset owners, inspectors, and certification bodies as a proven, traceable method for measuring surface profile, and is often written directly into project specifications.

Still need help?

If you experience an issue, check our troubleshooting guide or contact our support team directly. As a DeFelsko Authorised Service Centre (DASC), DFT Instruments provides calibration, repair, and technical assistance locally in the UK.

What’s Included:

-

Roll or box of Testex® Press-O-Film™ replica tape (grade of your choice)

-

Protective packaging

-

Burnishing tool (when supplied in kit form)

-

Pictorial instruction sheet

📞 To enquire about this product, contact our team today on: 01442 879494 or Complete the form.