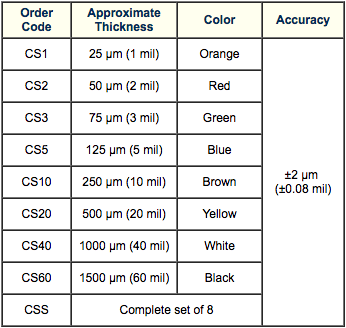

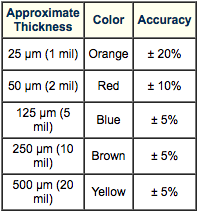

Coating Thickness Standards Overview

Certified Coating Thickness Standards are used to verify the accuracy and operation of coating thickness gauges and are an important component in fulfilling both ISO/QS-9000 and in-house quality control Coating Thickness Standards requirements. Contracts often specify that coating thickness measurements be taken by gauges whose measurement accuracy is traceable to a National Metrology Institute such as NIST or PTB.