PosiTest AT Series 10:02

This overview of the PosiTest® AT Pull-Off Adhesion Tester explains the general operation and procedure of performing an adhesion test.

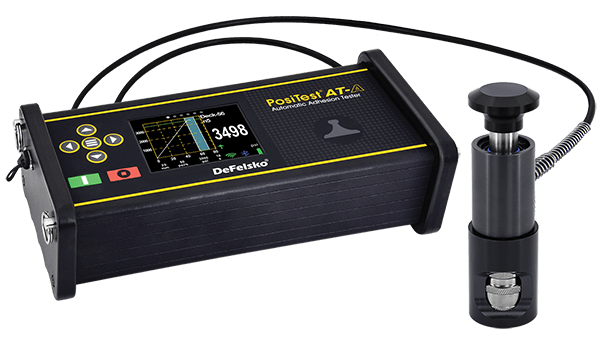

The PosiTest AT-A automatic adhesion tester is a fully automatic hydraulic pull-off adhesion tester designed for precision, repeatability, and ease of use. Built to withstand the toughest job sites, it provides highly reliable measurements of coating adhesion strength on metals, concrete, wood, and other substrates.

By automating the pull-off process, the Automatic Adhesion Tester eliminates operator variability and ensures consistent results across multiple tests. This makes it ideal for quality assurance programmes, compliance inspections, and any application where accuracy and documentation are critical.

Supplied exclusively in the UK by DFT Instruments, and supported by our DeFelsko Authorised Service Centre (DASC), the PosiTest AT-A comes fully calibrated, certified, and backed by local service, calibration, and technical expertise.

Prevent Coating Failures – Poor adhesion can lead to peeling, blistering, and delamination that compromise asset protection.

Compliance with Standards – Test to ISO, ASTM, EN, and other recognised industry standards.

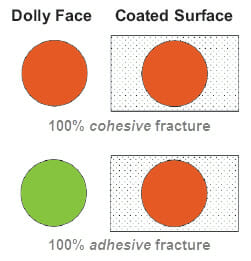

Evidence for Quality Control – Documented pull-off results and fracture analysis provide proof for contracts and audits.

Optimise Application Methods – Identify weaknesses in surface prep, primers, or coatings before they become costly problems.

Confidence in Performance – Ensure coatings will withstand real-world stresses over the long term.

Official UK Distributor – Genuine DeFelsko instruments supplied direct to the UK market.

DeFelsko Authorised Service Centre (DASC) – Calibration, servicing, and repair performed locally to factory standards.

Traceable Calibration Included – Every unit supplied with a calibration certificate traceable to NIST.

Fast UK Support – Local turnaround, expert advice, and one-day calibration service.

Trusted Experience – Over 25 years supporting UK industries from marine to aerospace.

This overview of the PosiTest® AT Pull-Off Adhesion Tester explains the general operation and procedure of performing an adhesion test.

A helpful video showing the self-alignment feature. Both the PosiTest AT-M Manual and PosiTest AT-A Automatic models compensate for misalignment.

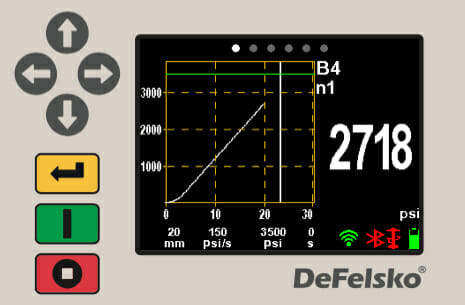

Simple controls to select dolly size, measurement units, and data storage at the touch of a button.

Low-cost, single-use dollies and plates remove the need for cleaning and can be kept as permanent records.

Kits include everything needed for testing straight out of the box.

Weatherproof, dustproof, and shockproof housing meeting or exceeding IP65 standards.

Supplied in a protective hard-shell case, with an optional upgrade to a heavy-duty Pelican case.

Two-year warranty included.

Calibrated to ±1% accuracy using a NIST traceable load cell.

Each instrument comes with a Certificate of Calibration traceable to recognised standards.

Self-aligning aluminium dollies ensure accurate measurements on both smooth and uneven surfaces.

Conforms to international standards including ASTM C1583/D4541/D7234/D7522, ISO 4624/16276-1, EN 12004-2, and more.

Four stand-offs available for a wide range of applications.

Supports dolly sizes from 10 mm to 50 mm, plus 50 × 50 mm tile and 50 mm C1583 options.

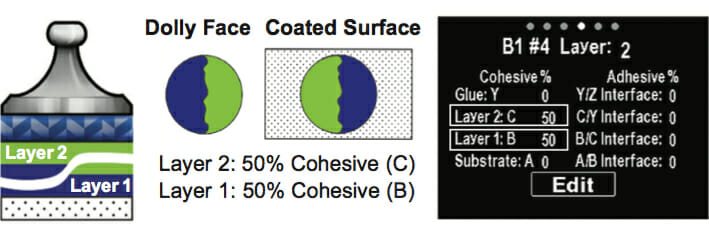

Internal memory stores maximum pull-off pressure, pull rate, test duration, dolly size, and fracture type.

Electronic hydraulic pump applies smooth, consistent pressure automatically.

Impact- and scratch-resistant touchscreen (with keypad for gloved operation).

Built-in Li-ion battery delivers 250+ tests per charge; USB-C port enables fast charging while in use.

Rotating display for easy use in horizontal or vertical positions.

Stores up to 100,000 results with pressure-time graphs, fracture type, and batch organisation.

Integrated USB, WiFi, and Bluetooth for seamless connection to PC, Mac, mobile devices, or PosiSoft Cloud.

PosiSoft Suite enables reporting, data sharing, cloud backup, and synchronisation across devices.

| Specification | ATA20 | ATA50 | ATA50T (EN 12004-2) | ATA50C (ASTM C1583 / EN 1542) |

|---|---|---|---|---|

| Dolly Size & Stand-Off | 20 mm | 50 mm | 50 × 50 mm Plate | 50 mm |

| Typical Applications | Higher bond-strength coatings on metals | Lower bond-strength coatings on wood, concrete, and plastic | Cementitious adhesives for tiles | Concrete surfaces and overlays |

| Range | 0.7 – 24 MPa 100 – 3500 psi 220 – 7550 N |

0.1 – 3.8 MPa 16 – 560 psi 220 – 7550 N |

0.1 – 3.0 MPa 13 – 440 psi 220 – 7550 N |

0.1 – 3.8 MPa 16 – 560 psi 220 – 7550 N |

| Resolution | 0.01 MPa (1 psi) | 0.01 MPa (1 psi) | 0.01 MPa (1 psi) | 0.01 MPa (1 psi) |

| Accuracy | ±1% Full Scale | ±1% Full Scale | ±1% Full Scale | ±1% Full Scale |

| Included Dollies | Ø20 mm aluminium (20 pcs) | Ø50 mm aluminium (8 pcs) | 50 × 50 mm steel plates (4 pcs, with threaded post) | Ø50 mm steel (4 pcs, ≥25 mm thickness) |

| Cutting Tool | 20 mm hole saw | 50 mm hole saw | – | 50 mm diamond-grit hole saw with arbor |

Protective coatings on steel structures.

Concrete overlays, flooring systems, and cementitious adhesives.

Industrial coatings in marine, oil & gas, and construction sectors.

High-strength bonding evaluations in aerospace and automotive.

Yes. Both the Manual and Automatic PosiTest AT are engineered for demanding field conditions. With a sealed metal housing, robust hydraulic pump, and industrial-grade pressure sensor, they’re built to withstand dust, water, and impact (IP65 rated). The Automatic model also includes rubberised grips and a shoulder strap for extra convenience when working on site.

All PosiTest AT kits come with self-aligning loading fixtures designed to meet international standards. The 20 mm and 50 mm models use precision aluminium dollies, while the 50 × 50 mm Tile and 50 mm C1583 kits are supplied with steel dollies. Both aluminium and steel dollies are intended for single use, which avoids cleaning, reduces contamination risk, and allows them to be kept as a permanent record of testing.

Every PosiTest AT kit includes ResinLab EP11HT epoxy adhesive, which is suitable for most coating systems and substrates. For specialist coatings or unusual applications, alternative adhesives may be required — our team can advise if a different adhesive is more appropriate.

Both instruments are certified to ±1% accuracy. The key difference is that the Automatic model applies hydraulic pressure electronically, removing potential operator influence and producing more consistent results, especially in formal inspection and quality assurance programmes.

20 mm: Best for high bond-strength coatings on metals or other strong substrates.

50 mm: Recommended for concrete, wood, and composites where adhesion is typically lower.

The choice of dolly size ensures the test is suited to both the substrate material and expected adhesion range.

Yes, for larger diameters. Customers report reliable performance on internal or external pipes greater than 200 mm in diameter, with a maximum glue gap of 0.5 mm. For smaller pipes, 10 mm or 14 mm dollies may be used where appropriate. Flat dollies are required for compliance with international standards, so curved dollies are not recommended.

The Automatic model uses a rechargeable Li-ion battery capable of more than 250 tests per charge. It features a USB-C port for fast charging, and the instrument can also operate while charging — ensuring uninterrupted use.

With a 50 mm dolly, the AT-A requires a priming pressure of 16 psi before recording measurements. Below this, results may not be consistent. The Manual model can be used more gradually at very low pressures, but both models maintain the same ±1% accuracy across their full scale.

The supplied epoxy cures within 24–48 hours, which suits most inspection schedules. For faster turnaround, some users employ cyanoacrylate (superglue) adhesives for lower-strength coatings. Always confirm compatibility with both the coating and the test dolly material.

There is no strict minimum, but adhesion results can be influenced if the substrate bends or deforms under load. ISO 16276 recommends a minimum of 3 mm for steel substrates. For thinner materials, support fixtures or backings should be used to prevent flexing during the test.

Adhesion testing is designed for rigid materials. Flexible substrates may distort the readings, while brittle substrates may crack or shatter during testing. In these cases, results may reflect substrate failure rather than coating adhesion.

Yes. Every tester is calibrated at the factory and supplied with a long-form Certificate of Calibration traceable to UKAS/NIST/PTB standards. This certificate documents actual test results, unlike basic “conformance” certificates offered by some competitors.

No specialist training is required. The gauges are straightforward to operate and are supported by clear manuals, quick guides, and tutorial videos. If you need help, our UK team offers ongoing telephone and email support.

Still need help?

If you experience an issue, check our troubleshooting guide or contact our support team directly. As a DeFelsko Authorised Service Centre (DASC), DFT Instruments provides calibration, repair, and technical assistance locally in the UK.

Automatic Adhesion Tester (AT-A)

Built-in rechargeable Li-ion battery + charger

Dollies (quantity varies by model)

Abrasive pad, cutting tool, adhesive, mixing sticks & palettes, cotton swabs

USB cable + PosiSoft software

Instruction manual & quick guide

Shoulder strap

Certificate of Calibration (traceable to NIST/UKAS)

Protective carrying case (upgradeable to Pelican)

The PosiTest AT-A combines automation, accuracy, and durability to deliver world-class adhesion testing—now available with full UK support and calibration through DFT Instruments.

📞 To enquire about this product, contact our team today on: 01442 879494 or Complete the form.