| Specification | Detail |

|---|---|

| Measurement Range | Up to ~3,000 µm / 120 mils on top stainless models; others vary by model |

| Accuracy / Tolerance | Manufactured with tight tolerances for notch heights; “Certificate of Accuracy” included on certified models |

| Units | Microns (µm) or mils, depending on model |

| Body / Material Styles | Stainless steel (8-sided dual-head, 6-sided), and aluminium (4-sided packs) |

| Packaging / Case | Certified & stainless versions include hard-shell case and instruction card; aluminium cards supplied in packs of 10 |

Wet Film Thickness Gauge

Measure Wet Paint & Coating Thickness Instantly

Wet Film Thickness Gauges let you gauge the thickness of uncured coatings; paint, enamels, varnishes and other wet films—quickly, simply, and without guesswork. Whether for pre-application checks, process adjustments or regulatory compliance, these mechanical gauges give you visual confirmation of wet film depth before it dries or cures.

Supplied in the UK by DFT Instruments, each gauge is built tough, includes a Certificate of Accuracy, and comes with a protective case so you can rely on your readings in the workshop or on site.

Features

-

Fast, Accurate Measurement – Notched Wet Film Thickness Gauges quickly check the thickness of wet paint, enamel and other coatings before curing.

-

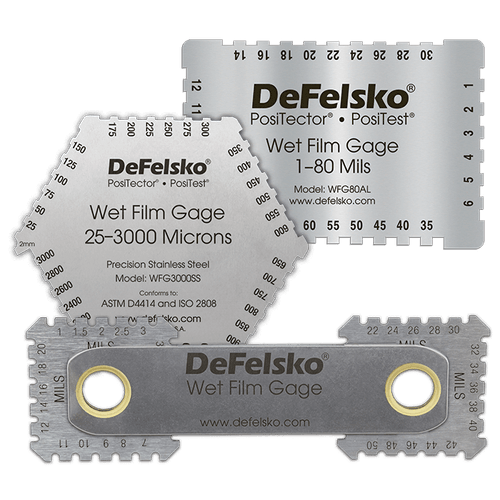

Three Durable Styles Available:

-

Certified Stainless 8-Sided Gauge – dual-head design with high resolution.

-

Stainless 6-Sided Gauge – robust, reusable option for everyday site work.

-

Aluminium 4-Sided Gauge – lightweight and economical, supplied in packs.

-

-

International Standards Compliance – Meets or exceeds ISO 2808, ASTM D4414, AS/NZS 1580.107.3, JIS K 5600-1-7, NF T30-125, US Navy NSI 009-32, and other recognised specifications.

Why Measuring Matters

-

Ensure Correct Film Build

If wet film is too thin, the cured coating may underperform (poor coverage, reduced durability). If too thick, drying problems, sagging or runs may occur. -

Optimise Material Usage

Knowing wet film thickness helps operators adjust spray settings, reducing overspray, conserving paint, and lowering costs. -

Consistent Quality Control

Frequent checks during application help maintain uniformity between batches, colours and surfaces—especially on large or complex jobs. -

Faster Troubleshooting

When defects appear after curing, knowing you had the correct wet film thickness rules out one major variable, speeding up root cause analysis. -

Meet Industry & Contract Standards

Many specifications reference wet film thickness (e.g. ISO 2808, ASTM D4414, AS/NZS 1580.107.3) for coating systems; having a reliable mechanical gauge helps ensure compliance.

Why Choose DFT?

-

Longstanding Field Experience

Since 1998, DFT Instruments has supported UK coating, finishing and paint-test industries—we understand what works in harsh site conditions. -

UK Calibration & Accuracy Guarantees

All stainless steel or certified models include a Certificate of Accuracy traceable to recognised standards, ensuring your audits or inspections are defensible. -

Variants to Suit Every Job

Choose between stainless hardened bodies (for heavy duty), economical aluminium cards (for temporary or disposable use), or certified dual-head “8-sided” versions when you need higher resolution. -

Rugged, Field-Ready Accessories

Hard-shell cases, instruction cards, pictorial guides and protective storage are all supplied so your gauge stays serviceable and accurate. -

Guidance & Support

We’ll help you choose the right style, range or number of notches; provide best-practice advice for reading and cleaning; and ensure your tools stay accurate over time.

Features & Benefits

-

Three construction styles: Certified Stainless 8-Sided, Stainless 6-Sided, and Aluminium 4-Sided—choose durability or economy depending on the job.

-

Dual measurement units: microns (µm) and mils, depending on the model.

-

High notch counts for finer resolution—for example, 40 notches on the dual-head 8-sided model.

-

Durable stainless steel bodies resist wear; aluminium 4-sided versions offer lightweight, economical alternatives.

-

Cards are compact; some styles are reusable, others are disposable or retained as permanent records.

Technical Specifications

Models & Range Comparison Table

| Model / Style | Range | Body Material | Notches / Resolution Details |

|---|---|---|---|

| Certified Stainless 8-Sided (WFG60/1500SSC) | 1–60 mils / 25–1,500 µm | Stainless steel | Dual-head; 40 notches; both mils and microns read-outs |

| Stainless 6-Sided | • 20–370 µm • 25–2,000 µm • 25–3,000 µm • 0.5–15 mils • 1–80 mils • 1–120 mils | Stainless steel | Various notch counts; includes edge-radius and chamfer checks |

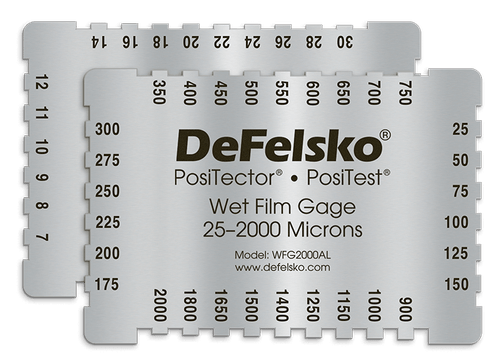

| Aluminium 4-Sided (Pack of 10) | 25–2,000 µm 1–80 mils | Aluminium | 30 notches; economical; suitable for single or limited re-use |

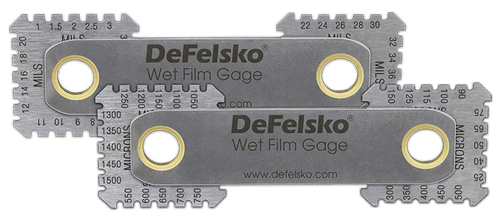

Certified Stainless 8-Sided WFT Gauge

-

Dual-Range Measurement – Two-sided design measures 1–1,500 µm on one face and 1–60 mils on the reverse for maximum flexibility.

-

High-Resolution Reading – 40 precision notches (5 per side) deliver exceptional resolution and accuracy.

-

Rugged Construction – Made from certified stainless steel for long-term durability in demanding coating environments.

-

Certified Accuracy – Supplied with a Certificate of Accuracy traceable to recognised standards for complete confidence.

-

Dual Units – Clearly marked in both microns and mils, eliminating conversion errors.

-

Protective Storage – Comes with a compact hard-shell case and a pictorial instruction card for easy reference and safe transport.

Stainless 6-Sided WFT Gauge

-

Wide Measurement Capability – 6-sided gauge with 24 or 36 precision notches, measuring coatings up to 3,000 µm (120 mils).

-

Multiple Range Options – Choose from six measurement ranges to suit different coating applications.

-

Robust Stainless Steel Body – Built from durable stainless steel for long-term accuracy and repeated field use.

-

Edge-Check Features (Imperial Models) – Include notches for verifying 1/16″ and 1/8″ edge radius and edge chamfers, meeting NACE SP0178 and PA Guide 11 requirements.

-

Edge-Check Features (Metric Models) – Include a notch to confirm a 2 mm edge radius, in line with ISO 8501-3.

-

Protective Accessories – Supplied with a compact hard-shell case and a pictorial instruction card for safe storage and easy reference.

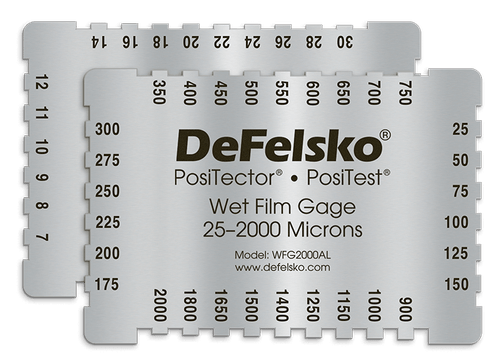

Aluminium 4-Sided WFT Gauges

-

Compact 4-Sided Design – 30 precision notches measure wet coatings up to 2,000 µm or 80 mils.

-

Lightweight & Economical – Manufactured from durable aluminium for an affordable, portable solution.

-

Convenient Card Size – Slim 5.7 × 8.25 cm (2.25″ × 3.25″) format fits easily in a pocket or tool kit.

-

Flexible Use – Can be disposed of, archived as a permanent record, or cleaned for re-use.

-

Packaged for Efficiency – Sold in packs of 10 for convenient stocking on site.

-

Choice of Units – Available in two ranges:

-

25–2,000 µm (Model WFG2000AL10PK)

-

1–80 mils (Model WFG80AL10PK).

-

FAQ’s

How do I read a wet film gauge correctly?

Place the gauge so the notches pass through the freshly applied coating. Lift it straight off and note the highest notch with coating transfer and the next highest that remains dry; your wet film thickness lies between those two readings.

When should I use the dual-head 8-sided version?

Choose it when you need wider measurement range, higher resolution, or both metric and imperial units on one tool.

Are aluminium cards accurate enough for professional work?

Yes—for many applications they are ideal. They are less durable and can bend, so for heavy-duty or precision tasks the stainless versions are recommended.

Do these measurements indicate final dry film thickness?

Not exactly. Curing and solvent evaporation reduce the final thickness—typically by 30–50 %. Use wet film readings as an application control, not as the final dry specification.

Which standards do these gauges conform to?

ISO 2808, ASTM D4414, AS/NZS 1580.107.3, JIS K 5600-1-7, NF T30-125, US Navy NSI 009-32 and others.

How should I care for and store these gauges?

Clean immediately after use to remove any wet coating. Store stainless gauges in their hard case and keep aluminium cards flat and dry to avoid bending.

Still need help?

If you experience an issue, check our troubleshooting guide or contact our support team directly. As a DeFelsko Authorised Service Centre (DASC), DFT Instruments provides calibration, repair, and technical assistance locally in the UK.

What’s Included:

-

Wet Film Thickness Gauge (model of your choice)

-

Protective case or sleeve (stainless models) or pack of 10 (aluminium models)

-

Instruction card / quick reference guide

-

Certificate of Accuracy (on certified stainless models)

Check your coating thickness before it cures to guarantee a perfect finish and save on costly rework.

📞 To enquire about this product, contact our team today on: 01442 879494 or Complete the form.