| Specification | Details |

|---|---|

| Range | 0.25 – 20 mils / 5 – 500 µm |

| Accuracy | ±(0.1 mil + 10%) / ±(2.5 µm + 10%) |

| Operating Temp | –100 °C to 230 °C (–150 °F to 450 °F) |

| Mechanism | Magnetic pull-off with gravity compensation |

| Scales | Dual—mils and microns |

| Calibration | Long-form traceable to PTB/NIST supplied |

| Warranty | Two years |

Magnetic Pull-Off Coating Thickness Gauge

The PosiPen is a mechanical, magnetic pull-off coating thickness gauge, engineered for exceptional accuracy on non-magnetic coatings—such as paint, enamel, plating, or galvanizing—applied to steel. Its precision micro-magnet and pull-trigger mechanism make it perfect for measuring in tight areas, on small parts, or across uneven surfaces.

Distributed in the UK by DFT Instruments, your PosiPen arrives fully calibrated with a long-form Certificate traceable to PTB/NIST, backed by local support and calibration services.

Features

- Can be used on small, hot or hard-to-reach surfaces

- Easy-to-Use

- Lightweight—easy to carry, just like a ball point pen

- Rugged—not affected by mechanical shock, acid, oil, water and dust

- No user adjustment required

- Highly wear resistant probe tip for long life and continuous accuracy

- Certificate of Calibration showing traceability to PTB included (Long Form)

Why PosiPen Matters

-

Perfect for Small or Hot Surfaces

Works effectively on narrow, hot, or hard-to-reach areas, including wire, machinery gaps, or cast metal. -

Ready for Extreme Conditions

Engineered for reliability under temperatures from –100 °C to 230 °C (–150 °F to 450 °F). -

Durability That Lasts

No electronics—just mechanical precision. Rugged enough to resist shock, oil, water, chemicals, and dust. -

Simplified Accuracy

No need for zeroing or calibration by the user. Just place, pull, and read—on either mols or microns scales. -

Trusted During Audits

Supplied with a calibration certificate traceable to national standards and trusted globally.

Why Choose DFT?

-

UKAS/PTB Calibration Included

No added costs—every gauge arrives ready for compliance. -

Authorised Local Service

Speedy UK calibration turnaround and expert technical support available. -

Genuine DeFelsko Quality

Official distributor status ensures authenticity, warranty coverage, and spare parts. -

Expert Advice On Demand

Guidance on surface preparation, user technique, and inspection best practices. - Trusted Partner Since 1998 – Over 25 years serving UK and Irish inspection professionals.

Features & Benefits

-

Precision Magnet – Delivers accurate readings on tiny or irregular surfaces.

-

Lightweight Design – Portable like a pen, it conveniently fits into shirt or coat pockets.

-

Built to Endure – Fully mechanical with a hardened probe tip and zero reliance on power.

-

Dual Measurement Scales – Reads in both mils and microns for flexibility.

-

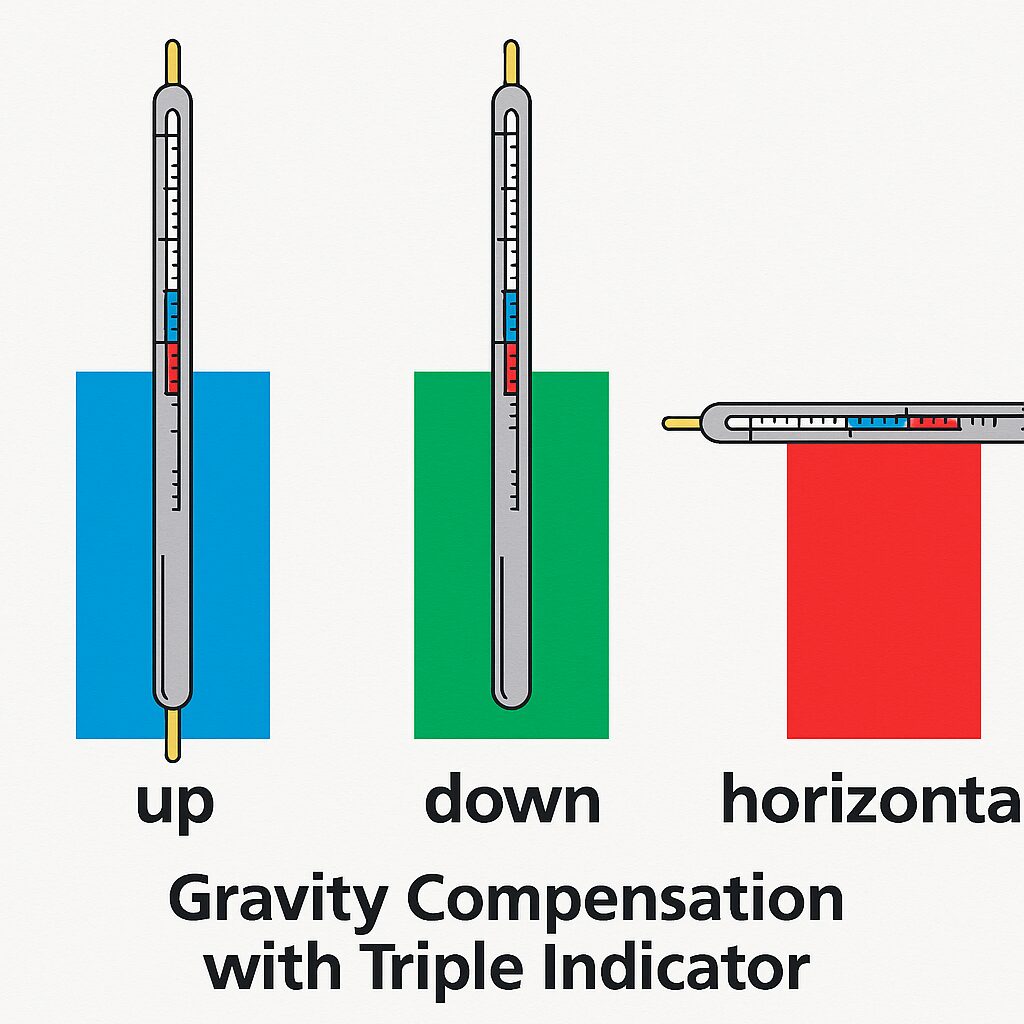

Gravity-Compensated Design – Colour-coded indicators (horizontal, down, up) ensure accuracy in any orientation.

-

Standards Compliance – Meets ASTM D7091/B499, ISO 2808, and other international standards.

Technical Specifications

How the PosiPen Works

-

Position the Gauge

Place the PosiPen tip flat against the coated surface and let the magnet make full contact. -

Pull Directly Away

Draw the instrument straight back from the surface while watching the appropriate indicator. -

Read the Value

When the magnet releases, note the measurement shown—this is the coating thickness.

The PosiPen is designed for use on small parts, hot surfaces, and areas that are difficult to reach, making it highly versatile for field and laboratory work.

Gravity Compensation with Triple Indicator

To ensure accuracy in any orientation, the PosiPen uses a colour-coded indicator system:

-

Red/Silver line – for horizontal surfaces (walls)

-

Green line – when pointing straight down (ground)

-

Blue line – when pointing straight up (sky)

This unique feature automatically compensates for gravity, delivering consistent readings whether you’re working overhead, at eye level, or below your feet.

FAQ’s

Is it calibrated out of the box?

Yes—it comes with a long-form certificate traceable to PTB or NIST, detailing actual readings from the factory lab.

How does it handle orientation?

Colour-coded guidelines help compensate for gravity:

-

Horizontal (red/silver),

-

Downwards (green),

-

Upwards (blue).

Can it measure on wire or small parts?

Absolutely—it works on ferrous wires as small as 18 AWG and tiny components thanks to its pinpoint magnet.

What happens on rough surfaces?

Like all dry film gauges, rough substrate can skew results. We recommend measuring the uncoated substrate (base metal reading) and subtracting it from later coating readings.

Can it measure nickel coatings?

Yes, if it’s electroless nickel with at least 8% phosphorus (non-magnetic). Electrolytic nickel (magnetic) may not be measured accurately.

Is user adjustment required?

No. Settings are fixed for durability—no zeroing is needed; just place, pull, and read.

Still need help?

If you experience an issue, check our troubleshooting guide or contact our support team directly. As a DeFelsko Authorised Service Centre (DASC), DFT Instruments provides calibration, repair, and technical assistance locally in the UK.

What’s Included:

For ultra-compact, precision coating thickness checks, the PosiPen Magnetic Pull-Off Gauge offers unmatched portability and reliability. Supplied with traceable calibration and full UK support from DFT Instruments.

📞 To enquire about this product, contact our team today on: 01442 879494 or Complete the form.